{Fulfilling challenging specifications of chilling operations demands tailored valve innovation. Our arctic 3-way globular assembly answers are produced to provide dependable work even at very low temperatures, typically below -150°C. These valves offer exquisite passage optimization in liquefied fluids such as nitrogen, oxygen, and argon, frequently applied in markets like LNG, experimental equipment, and diagnostic facilities. This firm stress resilient construction, including frictionless securing substances and rigorous manufacturing, to validate seal-tight execution. Explore the gains of upgrading your subzero system with our progressive 3-way spherical apparatus systems.

Premium Twin Seal and Vent Ball Valves

With respect to stringent uses, particularly where outflow is inadmissible, exemplary double block and bleed sphere valves offer unparalleled protection. This distinct design incorporates two standalone ball valve seals, further a bleed port, allowing for verification of the complete shut-off and detection of any expected drip. Generally employed in fuel processes, manufacturing fabrication, and cryogenic atmospheres, these components markedly improve productive stability and lessen the exposure of biospheric effect.

3-Way Freezing Globular Device Design

Its generation of three-way glacial round mechanism presents a specific engineering problem. These mechanisms are commonly employed in essential industrial uses where extreme temperatures must be held. Key concerns include element determination, in particular regarding fragility at decreased thermals, and the obligation for snug sealing to restrain leakage of ice-cold fluids. Advanced examination procedures and thorough assembling procedures are fundamental to confirm consistent operation and life under such strict performance situations.

Glacial Valve Efficiency in Vocational Applications

These demanding specifications of frozen tasks, such as coolant natural methane handling and fluid nitrogen storage, necessitate unfailing valve engineering. Integral block exhaust instruments provide a particularly robust and effective method to achieving zero-leak isolation while facilitating cyclical maintenance. Their design encompasses a primary mechanism with a small drain conduit, allowing regulated pressure emission during closure and resumption. This inherent aspect minimizes residual substance entrapment, thereby ensuring remarkable guarding and competence even under the most stringent functional cases. Furthermore, the capacity to track escape flow provides valuable analytical facts for function optimization.

Maintaining 3-Way Orbital Valve Fastening in Extreme High-Pressure Contexts

Achieving consistent closure performance with 3-way round valves becomes particularly important when operating within intense pressure conditions. The design should account for significant pressures and potential escape pathways. Specialized elements, often including high-performance metals like corrosion-resistant steel or exotic alloys, are essential to bear the extreme conditions. Furthermore, intricate interface geometries and careful construction processes are required to minimize distortion and guarantee a hermetic union even under fluctuating strain cycles. Regular assessment and maintenance overhaul programs are likewise vital for longevity and unbroken operational stability.

Frostbitten Ball Valve Leakage Prevention Strategies

Curtailing "leakage" from cryogenic "cryo valves" demands a multifaceted "approach". Initial "engineering" considerations are paramount; material "decision" must account for extreme "freezing points" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "constituent", meticulous "assembly" processes – including stringent weld "examinations" and non-destructive "investigation" – are vital to ensure structural integrity and eliminate voids that could become "channels". A "fundamental" component is proper "arrangement"; thermal "reduction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "care" – including periodic "review" for signs of wear and "repair" of any identified issues – is indispensable for maintaining a reliable, leak-tight "stopper”. Ultimately, a robust "schedule" incorporating these elements is necessary to ensure the safe and efficient "working" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "waste", safety "hazards", and costly "cessation”.

Twin Clamp and Drain Device Examination Techniques

For certifying the integrity and safety of critical piping installations, rigorous parallel barrier and release mechanism inspection processes are essential. These tests, often mandated by regulatory bodies and industry best standards, typically involve simulating simultaneous closure of two isolation devices while simultaneously ensuring the bleed system remains functional and correctly discharges any trapped commodity. A common process is to utilize a pressure trial where the system is pressurized to its maximum working pressure, and the escape rate around the closed valves is meticulously appraised. The escape instrument's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of assessment results, including any outliers observed, is indispensable for maintaining a reliable function.

Realizing Entire Block Discharge Device Efficiency

For achieving successfully govern pressure configurations, a thorough recognition of integral block escape apparatus capability is completely essential. These tailored devices generally respond to efficiently release unwanted strain from a configuration during specific working phases. A normal setup consists of a contained volume linked to the leading compression source, enabling specific regulated expulsion upon required. The innate configuration minimizes the hazard of beyond-limit pressure, protecting both the machinery and the adjacent setting. Regular check and servicing are important to confirm maximal efficiency.

Determining the Appropriate 3-Way Ball Valve for Cryogenic Fluids

Picking a appropriate 3-tri-ball component for cryogenic functions demands careful scrutiny of several critical components. The extremely low freezes inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present distinctive challenges. Material election is paramount; only materials with proven coherence and ductility at these temperatures, such as rust-resistant steel grades like 304L or 316L, or specialized metallic alloys, should be scrutinized. Furthermore, the mechanism's sealing functionality is vital to prevent escapements, requiring custom stem sealing templates and low-temperature oils. Finally, pressure gradings and actuation approaches, taking into account potential pressure fluctuations, must be completely matched to the system's specifications. Neglecting these considerations can lead to grave failure and safety threats.

Icy Spherical Valve Element Suitability Directory

Selecting the appropriate element for cryogenic ball valves is paramount, given the critical temperatures involved. This manual highlights common substances and their response when exposed to cryogenic fluids such as substance nitrogen, substance helium, and oxygen. Stainless steels, particularly kinds 304 and 316, often demonstrate adequate hardness and tarnishing resistance, though martensitic elements require careful consideration regarding vulnerability. Aluminum alloys can be suitable for certain applications, however, their workability and protection to specific chemicals needs intensive evaluation. Copper alloys, while offering some positives, may exhibit lessened behavior at these low temperatures. Consultation with makers and comprehensive examination is essential to confirm longevity and welfare in cryogenic operations.

Improving Double Block and Bleed Configuration Output

Realizing optimal functionality in double seal and release configurations hinges on a multifaceted technique. Careful assessment of element selection is paramount, with a focus on component correspondence and force classification. Regular examination of exhaust paths for obstruction is necessary, often involving the use of professional assessment tools. Furthermore, procedure refinement—including checking of passage rates and force variation—can noticeably advance overall configuration soundness and defense. Finally, conformity to supplier recommendations and the implementation of a detailed support plan are indispensable for long-term constancy and lastingness.

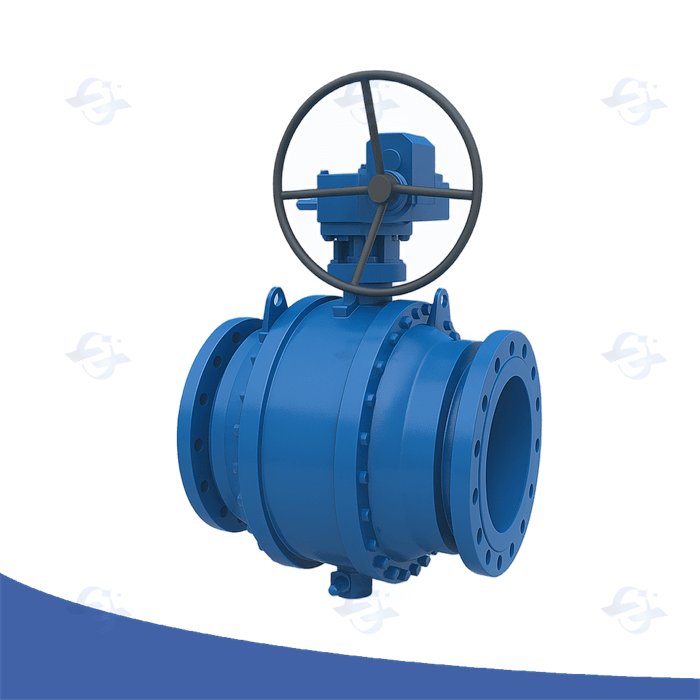

Trunnion Mounted Ball Valve

Trunnion Mounted Ball Valve