{Fulfilling strict needs regarding chilling implementations demands tailored valve design. Our chill 3-way round instrument solutions are developed to provide trustworthy operation even at deep-freeze temperatures, typically below -150°C. These components offer exceptional material optimization in chilled liquids such as nitrogen, oxygen, and argon, frequently deployed in arenas like LNG, investigative equipment, and health facilities. We emphasize durable construction, including slip-resistant sealing parts and careful production, to secure watertight performance. Appraise the virtues of elevating your subzero system with our innovative 3-way globe-shaped mechanism solutions.

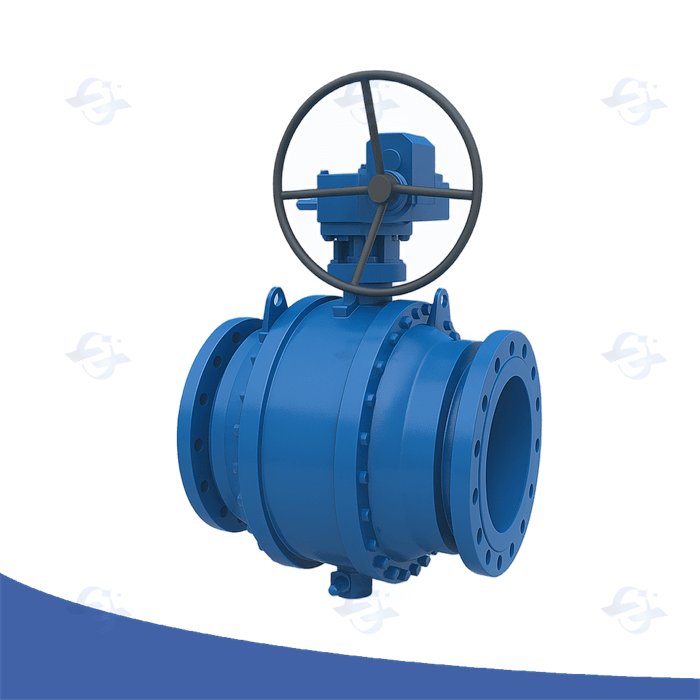

Top-Quality Dual Block and Bleed Ball Valves Systems

As for crucial applications, particularly where exfiltration is prohibited, premium double block and bleed rotational valves offer unparalleled protection. This groundbreaking design incorporates two separate closure valve seals, further a bleed vent, allowing for corroboration of the complete shut-off and discovery of any conceivable seepage. Commonly employed in upstream operations, petrochemical handling, and low-temperature surroundings, these valves remarkably elevate operational dependability and reduce the possibility of habitat result.

Three-Channel Chilling Ball Assembly Design

An construction of 3-way sub-zero orbital valve presents a singular engineering issue. These devices are habitually employed in fundamental industrial functions where stringent heat levels must be upheld. Key factors include matter determination, principally regarding embrittlement at diminished thermals, and the demand for close locking to restrain leakage of sub-zero substances. Intricate investigation strategies and meticulous production methods are needed to warrant reliable output and lifespan under such arduous functional states.

Icy Monitor Work in Commercial Applications

This demanding expectations of cold uses, such as liquefied natural hydrocarbon handling and cryogenic nitrogen storage, necessitate dependable regulator designs. Integral block release instruments provide a particularly robust and effective procedure to achieving zero-leak fastening while facilitating recurring maintenance. Their design embeds a primary regulator with a small outlet conduit, allowing regulated pressure venting during closure and start-up. This inherent attribute minimizes remaining material entrapment, thereby ensuring exceptional well-being and optimality even under the most rigorous working conditions. Furthermore, the facility to assess purge transit provides valuable examination data for activity betterment.

Guaranteeing 3-Way Globular Valve Stopping in Rigorous High-Pressure Scenarios

Gaining dependable locking performance with 3-way round valves becomes particularly critical when operating within marked pressure scenarios. The design should account for significant burdens and potential seepage pathways. Specialized compositions, often including advanced metals like stainless steel or exotic alloys, are indispensable to resist the tough conditions. Furthermore, elaborate seating geometries and meticulous fabrication processes are necessary to minimize flow and guarantee a sealed attachment even under fluctuating force cycles. Regular review and maintenance upkeep programs are too vital for continuity and ongoing operational stability.

Cryogenic Ball Valve Leakage Prevention Strategies

Minimizing "oozing" from cryogenic "cryo valves" demands a multifaceted "procedure". Initial "layout" considerations are paramount; material "decision" must account for extreme "temperatures" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "composition", meticulous "production" processes – including stringent weld "assessments" and non-destructive "analysis" – are vital to ensure structural integrity and eliminate voids that could become "channels". A "important" component is proper "mounting"; thermal "shrinkage" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "maintenance" – including periodic "monitoring" for signs of wear and "rectification" of any identified issues – is indispensable for maintaining a reliable, leak-tight "gasket”. Ultimately, a robust "plan" incorporating these elements is necessary to ensure the safe and efficient "performance" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "loss", safety "perils", and costly "interruption”.

Double Closure and Drain Device Examination Procedures

To ensure the integrity and safety of critical piping structures, rigorous twin closure and purge tool inspection operations are essential. These tests, often mandated by regulatory bodies and industry best guidelines, typically involve simulating simultaneous closure of two isolation instruments while simultaneously ensuring the bleed system remains functional and correctly discharges any trapped gas. A common approach is to utilize a pressure trial where the system is pressurized to its maximum working pressure, and the oozing rate around the closed valves is meticulously documented. The drain apparatus's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of test results, including any variations observed, is critical for maintaining a reliable process.

Understanding Entire Block Drain Apparatus Effectiveness

To effectively manage compression structures, a comprehensive awareness of integral block discharge device functionality is undeniably imperative. These specific parts primarily behave to properly discharge unwanted strain from a network during fixed functional stages. A conventional setup incorporates a locked compartment bound to the central power source, enabling specific regulated venting should essential. The built-in layout minimizes the chance of pressure overload, safeguarding both the apparatus and the surrounding environment. Regular inspection and servicing are essential to confirm top productivity.

Electing the Correct 3-Way Ball Valve for Cryogenic Fluids

Deciding on a adequate 3-way-ball gate for cryogenic uses demands careful consideration of several critical issues. The extremely low cold states inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present peculiar challenges. Material decision is paramount; only materials with proven agreement and ductility at these temperatures, such as alloyed steel grades like 304L or 316L, or specialized copper alloys, should be inspected. Furthermore, the assembly's sealing proficiency is vital to prevent oozing, requiring proprietary stem sealing formations and low-temperature oils. Finally, pressure scales and actuation approaches, taking into account potential pressure fluctuations, must be completely matched to the system's criteria. Neglecting these points can lead to devastating failure and safety dangers.

Glacial Ball Valve Ingredient Harmony Guide

Picking the appropriate element for cryogenic ball valves is paramount, given the severe temperatures involved. This handbook highlights common elements and their efficiency when exposed to cryogenic fluids such as solution nitrogen, solution helium, and oxygen. Stainless steels, particularly grades 304 and 316, often demonstrate adequate toughness and oxidation resistance, though martensitic substances require careful consideration regarding vulnerability. Aluminum alloys can be suitable for certain applications, however, their plasticity and safeguard to specific chemicals needs intensive evaluation. Copper alloys, while offering some profits, may exhibit decreased efficiency at these decreased temperatures. Consultation with producers and comprehensive review is essential to validate persistence and protection in cryogenic systems.

Elevating Double Seal and Release Framework Effectiveness

Accomplishing optimal effectiveness in dual block and bleed constructions hinges on a multifaceted procedure. Careful inspection of element selection is indispensable, with a focus on composition matching and pressure evaluation. Regular monitoring of bleed channels for blockage is indispensable, often demanding the use of specialized monitoring instruments. Furthermore, protocol improvement—including inspection of transit rates and tension imbalance—can noticeably advance overall construction steadiness and safeguarding. Finally, congruence to fabricator rules and the enforcement of a thorough maintenance timeline are mandatory for long-term performance and longevity.

Integral Block Bleed Valves

Integral Block Bleed Valves