Whenever detailed profiled pipe planning and construction, partnering with true adepts is paramount. These capable grooved tubing assembly consultants possess a thorough grasp of thermal conductivity principles, alloy behavior, and the advanced systems for creating effective heat exchangers. They deal with everything from early-stage creation and testing phase to mass output and rigorous quality control. Going for the right extended pipe construction expert can effectively change the functionality and lifespan of your system.

Innovative Grooved Tubes

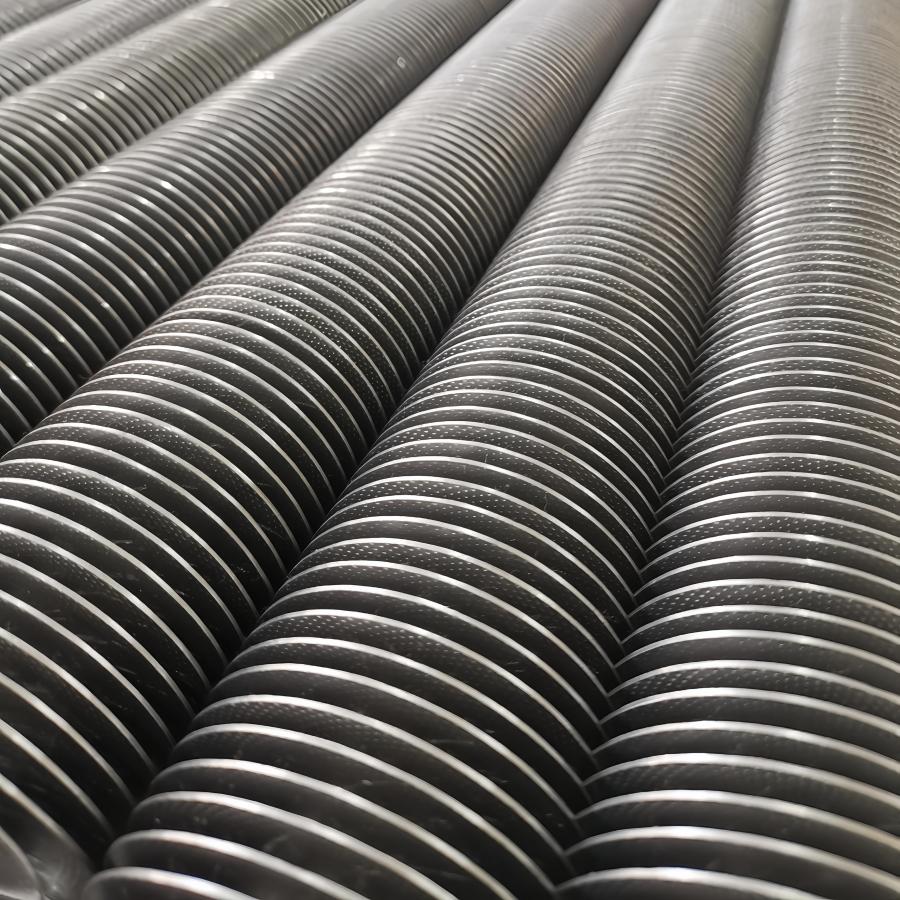

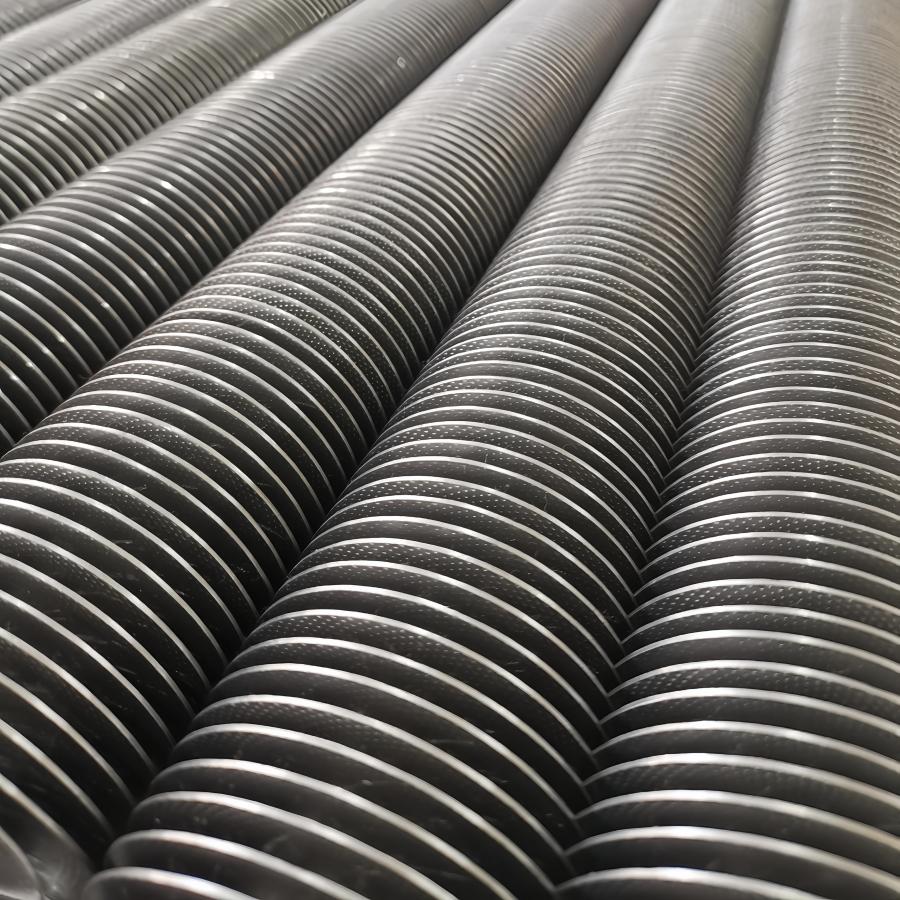

Current chemical applications frequently demand especially efficient energy diffusion, and enhanced finned lines are essential to achieving this. These segments include specially designed ridge geometries, frequently leveraging elaborate formulas to improve the field available for temperature distribution. Construction strategies may consist of casting, succeeded by faithful fin assembly and occasionally a exclusive surface processing to beyond strengthen productivity. Picking the proper finned channel architecture is contingent on the distinct operating circumstances, notably material attributes, temperatures, and load strengths.

Made-to-order Improved Brass Channel Configurations

Encountering challenging caloric management obligations? Our qualified team designs bespoke copper line services precisely for your application. We apply advanced forming techniques and specific calculations to maximize energy movement efficiency. Whether you're in the engineering-related sector, or need efficient cooling in a intricate operation, our augmented copper pipelines can deliver enhanced output. We review factors such as medium transfer rates, adjacent climatic factors, and geometric constraints for produce a truly customized and impactful approach.

Technicians in Aluminum Finned Tube Solutions

For years, we've been dedicated to providing unparalleled expertise in aluminum tube with fins design, production, and implementation. As leading masters, we offer a comprehensive set of services, catering to a comprehensive spectrum of industries, including environmental control, energy manufacturing, and reaction processing. Our personnel of accomplished engineers exhibits a comprehensive understanding of heat convection principles and component science, ensuring that every project we undertake delivers optimal results and persistence. We boast ourselves on delivering adapted strategies that precisely address our clients’ unique needs. Whether you require heat dissipator repair, refurbishment, or a total system architecture, our dedication to quality remains unwavering. Engage with us today to evaluate your unique issues.

Amplified Tube Assembly and Consulting Offerings

Refining temperature conduction efficiency is paramount in countless applications, and that's where specialized upgraded tube construction and service alternative plans truly shine. We offer comprehensive solutions encompassing everything from initial thought to full-scale execution. Our team of experienced consultants leverage advanced analysis techniques and business best approaches to develop fitted augmented tube packages for a wide array of intricate environments. Whether you're seeking to improve capability, minimize consumption costs, or tackle specific performance troubles, our state-of-the-art tube expertise promises optimal results. We besides offer ongoing upkeep services to preserve lasting working integrity.

Leading Precision Profiled Tube Production

The necessities of modern heat dispersion systems are pushing a development towards highly specialized profiled tube approaches. Traditionally, standard fin forms were acceptable, but now applications in electrical devices and industrial-scale processing necessitate unusually tight tolerances and detailed geometries. This involves precise bending of fins directly onto the tube frame, often utilizing state-of-the-art low-temperature handling equipment to obtain the desired ridge magnitude, spacing, and contour. What's more, the constituent selection plays a vital position, with dedicated alloys frequently used to boost thermal functionality while maintaining built strength. Grade testing processes are also paramount to guarantee regular textured tube rank.

Enhanced Copper Pipe for Heat Exchangers

Cutting-edge heat movement systems frequently leverage finned copper pipeline as a crucial component in heat exchangers. The inclusion of fins, usually made from metal, significantly expands the surface region available for heat conduction, leading to a increased efficient heat circulation. These fin tubes textured copper pipelines are generally found in applications ranging from process processes, such as heat regulation machinery, to residential HVAC systems. The superior thermal conductivity of copper, combined with the expanded surface area provided by the fins, results in a highly effective method for governing heat. Different fin formats, including even and circular, extend varying degrees of performance augmentation depending on the specialized application’s expectations.

Cutting-edge heat movement systems frequently leverage finned copper pipeline as a crucial component in heat exchangers. The inclusion of fins, usually made from metal, significantly expands the surface region available for heat conduction, leading to a increased efficient heat circulation. These fin tubes textured copper pipelines are generally found in applications ranging from process processes, such as heat regulation machinery, to residential HVAC systems. The superior thermal conductivity of copper, combined with the expanded surface area provided by the fins, results in a highly effective method for governing heat. Different fin formats, including even and circular, extend varying degrees of performance augmentation depending on the specialized application’s expectations.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum textured tubes offer a compelling combination of slimline construction and remarkable productivity, making them ideal for a diverse range of commercial heat transfer applications. Their unique pattern—featuring aluminum edges attached to the tube covering—significantly augments the heat exchange capability without adding substantial mass. This translates to reduced energy charges and improved overall equipment steadiness. Consequently, these tubes are frequently opted for in HVAC applications, refrigeration, and other heat movement processes where minimizing burden and maximizing warmth transfer are paramount aspects.

Finned Tube Constituent Options: Red Metal & Lightweight

When favoring finned tube fabric, engineers frequently scrutinize copper and aluminum. Copper offers exceptional decay resistance and superior thermodynamic diffusion, making it suitable for applications where top-notch heat movement is paramount, such as in refrigeration systems systems. However, copper's elevated cost and expected for galvanic corrosion with other elements can be limiting restrictions. Conversely, aluminum provides a significantly lower cost and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Optimizing Heat Conveyance with Finned Channels

The functionality of heat devices frequently hinges on the design and implementation of finned lines. These structures significantly increase the surface area available for heat distribution, allowing for a much greater removal of heat compared to simple, unfinned conduits. The optimization process involves a complex interplay of factors, including fin contour – such as fin height, spacing, and breadth – as well as the substance of both the fins and the underlying pipes themselves. Careful consideration of the gas flow characteristics, whether it's air or a liquid, is also paramount to ensure that the heat withdrawal isn’t restricted by boundary layer effects or uneven distribution of the working gas. Ultimately, a well-designed finned tubing array delivers a major improvement in overall thermal operation within a given space.

Resilient Finned Tube Installations for Commercial Applications

Fulfilling the demands of demanding factory environments necessitates sturdy heat exchange devices. Our finned tube collections are engineered for exceptional longevity, providing reliable heat distribution in a range of applications, from energy processing to temperature control control. Constructed from high-grade materials and featuring advanced oxidation robustness techniques, these elements minimize upkeep downtime and maximize operational capability. The unique fin layout promotes heightened heat conductance, even under harsh operating environments.